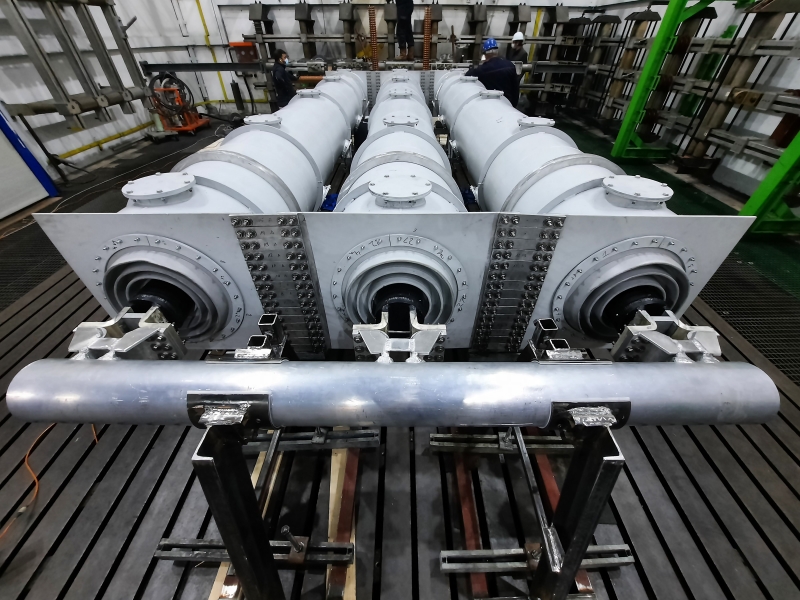

ALPE - Isolated Phase Busbars (IPB)

PURPOSE

Isolated Phase Busbars (IPB) type ALPE are an integrated transmission line system designed mainly for:

- deriving power from medium and high power generators,

- making connections of devices in systems of high short-circuit power,

- making group connections of single-phase transformers,

- making connections of the power supply system of own needs,

- distribution of power in plants.

GENERAL CHARACTERISTICS

ALPE type busducts are reliable power installations in the voltage range from 7.2 to 36 kV and rated current from 1.25 to 18 kA, with air insulation and natural cooling. They are adapted for both indoor and overhead operation. They can be operated in dusty and humid conditions.

ALPE type busducts can be made in two varieties:

Without overpressure, which means that the air inside the busduct is at atmospheric pressure.

With an overpressure system, where a small overpressure (1 kPa) of dry air is maintained inside the busbar with the help of appropriate installation and apparatus.

The dry air system is permanently connected to the outer casing, and with the help of a reducing station, the pressure inside the busbar is automatically controlled and regulated. The dry air overpressure, maintained continuously inside, completely eliminates the phenomenon of moisture condensation on insulating elements and prevents the penetration of dust particles.

ALPE type busducts are characterized by:

a rich series of types, guaranteeing their optimal selection for operating conditions,

self-supporting design, allowing for spans of up to 12 m standard length,

use of hatches providing access to insulators and bolted connections,

high reliability, low operating cost,

low electric field strength escaping from the shield,

resistance to corrosion,

high degree of electric shock safety.

CONSTRUCTION

IPB ALPE - the tube-shaped enclosure contains the conductor of one phase.

Enclosure

The busduct enclosure is circular in shape and made of aluminum, and is a self-supporting, all-welded structure to ensure tightness. The enclosure has inspection and mounting hatches for easy access to insulators. In positive-pressure designs, the ends of the screen are closed with bushing insulators. For better heat exchange with the environment, the inner surface of the enclosure is painted black. The outer surface of the enclosure is painted in any color from the RAL color palette (the standard color is RAL 7035).

The busbar is rated IP65 - dustproof and waterproof.

Conductors

Phase conductors in the form of tubes or aluminum profiles are supported on support insulators. The appropriate design of attaching the conductor rails to the insulators ensures free axial movement of the rail relative to the enclosure, eliminating the effects of the phenomenon of thermal linear expansion.

Support insulators

Standard busbar designs use post insulators made of epoxy resin. The insulators are used as fasteners for the conductors in the enclosure.

Bushing insulators

Bushing insulators are used in basic solutions as a barrier separating the zone of the busbar with dry air overpressure, from the zone with atmospheric pressure, or in installations without overpressure as a barrier to prevent moist air from being sucked into the busbar during the opening of connection covers to transformers or generators during inspection and service.

Compensation elements

Busducts are equipped with compensation elements for the conductor and enclosure which compensate for axial displacements caused by the phenomenon of thermal expansion and eliminate the transmission of vibrations from power equipment.

The conductor compensator is made of appropriately selected single aluminum flexible corrugated joints welded into the current bus string.

The enclosure compensator, made of extruded aluminum sheet, compensates for elongation and ensures the tightness and continuity of the section.

Enclosure compensator of busduct connections with connection covers to transformer, generator, etc. made of silicone rubber which compensates for enclosure elongation and transmission of vibrations to busducts emitted by cooperating equipment.

Supporting elements

Busducts are standardly equipped with aluminum support elements by means of which they are attached to supporting structures, beams or ceilings.

Electrical apparatus

The design of busducts allows the installation in special covers or directly in the enclosure of electrical apparatus such as switches, current and voltage transformers, lightning arresters and others.

Connections to devices

Connections to devices such as transformer, generator, switchgear, etc. are made of aluminum enclosures. The terminals of the equipment are connected with flexible connectors, copper or aluminum with silver-plated or tin-plated contact surfaces. The shields have suitable hatches or are designed to provide easy access to or easy removal of demountable connections.

Protection against direct contact

Protection against direct contact is provided by aluminum busbar enclosures, with IP65 protection level, and connection covers which are resistant to deformation and stresses occurring during normal operation.

Protection against indirect contact

ALPE type busducts operate in the so-called "short circuit" system of screens. At all end sections, i.e. at the transformer, generator and tapping, the screens of the individual phases are connected by welded aluminum jumpers of appropriately selected cross-section. Thus, the screens of all phases electrically form a single unit, which is connected to the main grounding terminal.

Design and calculations.

Design and calculations are performed by experienced designers, combining specialized engineering knowledge and experience with specialized software. As a result, after the consultation process, we provide the most optimal design solutions that meet the required technical parameters and operating conditions, and at the same time are the most advantageous from the point of view of the investment budget.

Type tests

Busducts are subjected to type testing, carried out in accordance with

international standards (ANSI, IEC, EN) by a prestigious, accredited, independent certification body. Type testing, which is a special requirement of the project, can be carried out at the expense of the customer, after agreeing on all the terms of implementation.