Cooperation

ALSTEMA sp. z o.o. is a company with over twenty years of tradition and modern technical, production and research facilities. The company is a specialized manufacturer of equipment directed mainly to the energy sector, although its production potential and experience allow it to carry out technologically advanced projects for other industry segments.

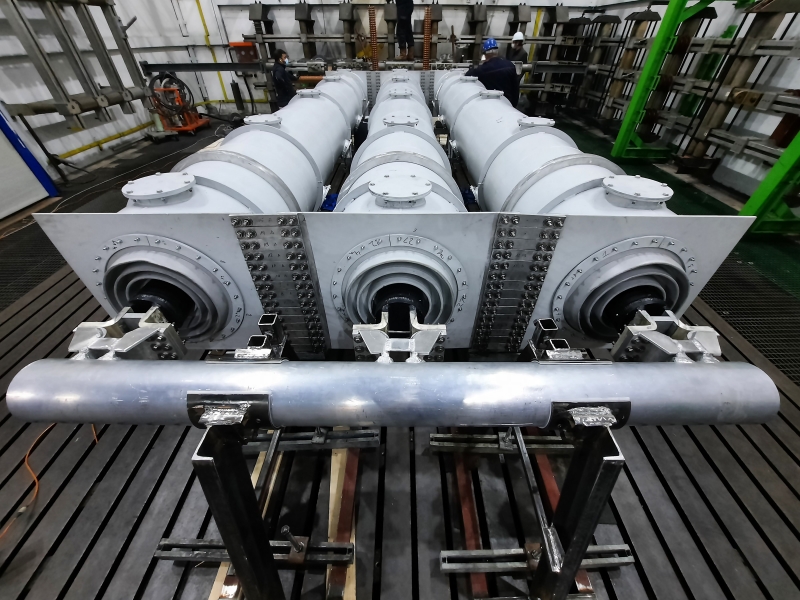

ALSTEMA sp. z o.o. has two production halls with a total usable area of more than 8,000 m2, enabling the realization of tasks with significant weights and dimensions. The production cycle is based on modern machinery, which consists of CNC equipment at each stage for, among other things, laser beam and water jet sheet metal cutting, sheet metal rolling, sheet metal edging and machining. Alstema has welding robots to fully automate longitudinal and circumferential pipe welding processes. Paint coatings are applied in a modern paint shop, using hydrodynamic and electrostatic technology.